General Information

General InformationGreen Roofs

Rainwater Harvesting

Ponds and Wetlands

Energy-Efficient Building

Design Principles

Weatherseals

Building Gaskets

Glazing Gaskets

Timber Glazing

Air-Vapor Films

Attic Access

Ventilation

Sealants

Shim Screws

Wood Repair

Documents

Waterproofing

GLAZING GASKETS

Our glazing gaskets offer a simple and reliable method for dry-mounting glass in fixed or operable wood or metal frame. They waterproof as well as caulks and traditional glazing tapes, but they cushion the glass better, and they don’t bond to it. Since the glass “floats” between two gaskets, the likelihood of glass breakage from thermal movement, wind stresses, or mechanical shock, is greatly reduced. If the glass is ever broken, it can be easily replaced without damaging the trim or finish.

MATERIAL: Our glazing gaskets are made of cellular (“sponge”) EPDM rubber, a synthetic rubber known for its outstanding sunlight stability. An adhesive backing holds the gasket in place until the glass is installed.

TYPES: We offer four standard glazing gaskets, two with adhesive backing and two for insertion in grooves.

GG05 |

GG10 |

GG23 |

GG25 |

GG05 and GG10 have self-adhesive backings so they are suitable for installation on wood, plastic, or metal surfaces. GG05 measures 1/8” x 3/8” (3mm x 9mm), and compresses to 1/16” (1.5mm). GG10 has an adhesive backing, measures 1/4” x 3/8”(6mm x 10mm), and compresses to 1/8” (3mm). GG10 has a deeply ribbed surface and a hollow interior that give it sufficient resilience to accommodate minor bowing in the framing or glass, features that make it suitable for both on-site and shop glazing of any size insulated unit. Since GG05 does not have the hollow interior, it requires clamping pressure for proper compression and is recommended for shop glazing of window sash and doors that are too thin for GG10, but only where the glass area is less than fifteen square feet. We stock GG05 and GG10 in black only.

GG23 and GG25 are designed for installation in a groove in wood. They are made from two types of EPDM rubber: a compressible cellular EPDM plus an installation dart of solid EPDM. GG23 measures 1/8" x 3/8" (3mm x 10mm) and compresses to 3/32" (2mm). GG25 measures 3/16" x 3/8" (5mm x 10mm) and compresses to 1/8" (3mm). We stock GG23 and GG25 in black, brown, and white.

INSTALLATION: When applying GG05 or GG10 with self-adhesive backing, all surfaces should be free of dust, oils, or waxes. If the weather is cold, heat up the wood or metal with a hot air gun to improve adhesion (the gaskets will not stiffen in cold weather). Surface conditions and weather will not affect installation of GG23 or GG25.

Cut the gaskets slightly longer than needed. When gaskets are applied to fixed stops, they should be cut square and tightly butted at corners, except for GG10 which can be bent 90° around a corner without cutting so only one joint is required, typically at the center of the top. When the gaskets are applied to stop molding, let them extend slightly beyond the ends so that there will be ample material to make a watertight corner. Mitering is necessary when stops are to be mitered. When installing GG05 or GG10, remove the release paper to expose the adhesive, and press them firmly in place. For the best bond, roll with a steel or rubber roller.

If the window or door is not well sheltered from the rain, a cap bead of caulk is recommended over the bottom exterior gasket to assure proper drainage. Although the gaskets can be painted with water-base paints to match any trim color, when left unpainted they provide a clean sight line with any wood finish.

Since the gaskets are approximately 3/8" wide, the stops should be at least 1/2” thick, preferably at least 5/8” to allow sufficient room for the glass to expand. Always set large panes of glass on hard rubber setting blocks located at the quarter points of the bottom of the glass (divide the width of the glass by four and measure this distance from either bottom corner) and use GG10 or GG25 instead of GG05 or GG23 whenever there is sufficient room. If the sash will frequently be wet by rain, drill bottom weep holes and apply a cap-bead of caulk over the bottom exterior gasket.

Although the same gasket is usually used on both sides, it is possible to use a thick gasket on the exterior for better sealing and a thinner, less visible gasket on the interior. Use the following table to determine the required space between the interior and exterior stops:

| Interior Gasket | Exterior Gasket | Space Between Stops |

| GG05 | GG05 | 1/8" (3mm) + glass thickness |

| GG05 | GG10 | 3/16" (5mm) + glass thickness |

| GG10 | GG10 | 1/4" (6mm) + glass thickness |

| GG23 | GG23 | 5/32" (4mm) + glass thickness |

| GG23 | GG25 | 3/16" (5mm) + glass thickness |

| GG25 | GG25 | 1/4" (6mm) + glass thickness |

MOUNTING GLASS IN RABBETED OPERABLE SASH: Generally window sash must be at least 2" thick to provide sufficient space for the glass, gaskets, and removable stop. The removable stop can be on the interior or exterior, but interior stops generally require the least maintenance. If the window is frequently wet by rain, drill weep holes through the sill and apply a cap-bead of caulk over the bottom exterior gasket.

installing GG05 in operable sash |

finished installation with GG23 |

installing GG23 in operable sash |

finished installation with GG23 |

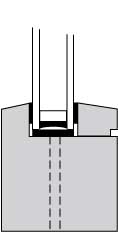

MOUNTING FIXED GLASS BETWEEN STOPS: One stop should be glued or caulked in place and the other is removable. The removable stop can be on the interior or exterior, but interior stops generally require the least maintenance. The stops should be at least 5/8” thick, preferably 3/4” to allow sufficient room for the glass to expand. Since there is usually plenty of space when mounting fixed glass and clamping is often not practical, GG10 or GG25 are always preferable to GG05 or GG23. Always set large panes of glass on 1/4” hard rubber setting blocks located at the quarter points of the bottom of the glass (divide the width of the glass by four and measure this distance from either bottom corner). If the sash will frequently be wet by rain, drill bottom weep holes and apply a cap-bead of silicone caulk over the bottom exterior gasket. The sill detail for fixed glass is different than the jamb and header detail, since both the outer stop and the sill must be beveled to shed water. A drip groove in the bottom of the sill will keep water from running back to the building. If the window is frequently wet by rain, drill weep holes through the sill and apply a cap-bead of caulk over the bottom exterior gasket.

installing GG10 between stops

finished installation wit GG10 showing bottom exterior cap bead of caulk

installing GG25 between stops

finished installation with GG25 showing bottom exterior cap bead of caulk

PRICING:

GG05 Glazing Gasket, black, 328 ft rolls - $44.00

GG05 Glazing Gasket, black, cut to length - $0.32/ft

GG10 Glazing Gasket, black, 328 ft rolls - $68.00

GG10 Glazing Gasket, black, cut to length - $0.44/ft

GG23 Glazing Gasket, black, bronze, 328 ft rolls - $88.00

GG23 Glazing Gasket, black, bronze, white, cut to length - $0.56/ft

GG25 Glazing Gasket, black, bronze, white, 328 ft rolls - $104.00

GG25 Glazing Gasket, black, bronze, white, cut to length - $0.64/ft