General Information

General InformationGreen Roofs

Rainwater Harvesting

Ponds and Wetlands

Energy-Efficient Building

Waterproofing

EPDM Roofing

Preparation

Basic Procedure

Multiple Walls

Details

Folded Inside Corners

Molded Inside Corners

Taped Inside Corners

Molded Outside Corners

Taped Outside Corners

Posts

Skylights

Outside Edges

Inside Edges and Sills

Edge Transitions

Pipe Boots

Curved Penetrations

Roof Drains

Scupper Drains

Overlap Seams

Butt Seams

Edges

Coverings

Components

Acrylic Roofing

Documents

EPDM ROOFING: BASIC PROCEDURE

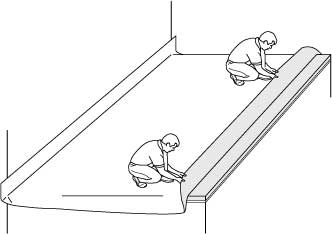

The following illustrations describe how EPDM rubber can be used to waterproof a simple shed roof with three sides open and a fourth side intersecting a wall. Although the procedures show the rubber fully adhered to the roof surface, when the rubber is to be covered with materials weighing at least five pounds per square foot such as floating wood decks, concrete pavers, gravel, or soil, it is only necessary to adhere the first few feet in from the edges, up the walls, and over the edges.

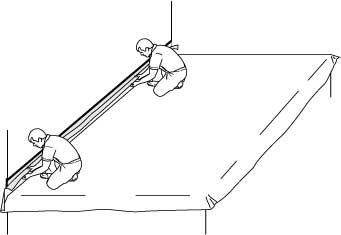

For safe delivery, we supply all rubber roof sheets folded and boxed. Since the rubber weighs about one-third of a pound per square foot, sheets up to 500 square feet can be carried by two people, but larger sheets can be quite heavy and difficult to manage. One solution is to rent a light-duty type crane (the type used to install commercial signs are relatively inexpensive). When using a crane, make certain the spot where the rubber is set down can handle the weight!

STEP 1: Using a pencil, mark the desired

rubber perimeter on the wall and roof edges.

STEP 2: Apply Termination Tape to the wall just

below the line.

Do not remove the protective paper.

STEP 3: Apply Termination Tape to the roof edges

just

above the lines. Do not remove the protective paper.

STEP 4: Apply Termination Tape to connect the wall

and

roof tapes

so the entire rubber perimeter is sealed.

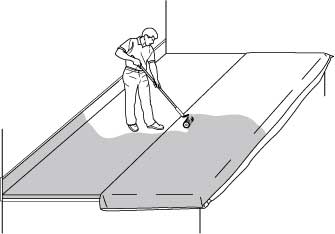

STEP 5: Pull the rubber from the

shipping box and drag it across the roof.

STEP 6: Unfold the sheet by pulling it across the roof.

Flipping the sheet will force air underneath so it floats into place.

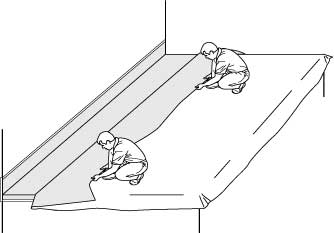

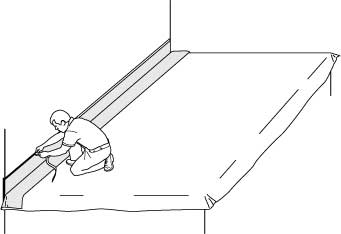

STEP 7: After the sheet is in postion, fold back the edge

adjacent to the wall. Wait at least an hour for the rubber to “relax”.

STEP 8: Pull back the folded edge adjacent to the wall,

taking

care not to move the remainder of the sheet.

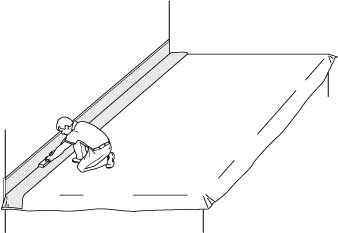

STEP 9: Using a paint roller, apply Bonding

Adhesive to the exposed rubber, roof, and wall.

STEP 10: After the adhesive is dry, carefully push back the

sheet. To prevent wrinkles, avoid creasing in the leading edge.

STEP 11: Using a clean wood board, press the rubber

firmly into the corner where the roof and wall meet.

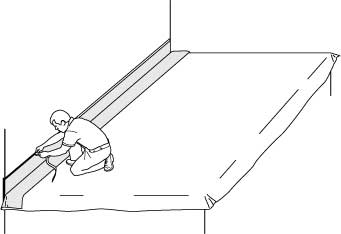

STEP 12: Peel the protective paper off the Termination

Tape on the wall to expose the tacky tape surface.

STEP 13: Slowly lift the sheet onto the wall,

pressing it into the adhesive and finally into the tape.

STEP 14: Firmly roll the rubber on

the wall to insure a good bond.

STEP 15: Pull back the opposite edge

to expose the other half of the roof.

STEP 16: Apply Bonding Adhesive to the

exposed

parts of the rubber and the roof.

STEP 17: After the adhesive is dry, carefully push

back the

sheet. To prevent wrinkles, avoid creasing in the leading edge.

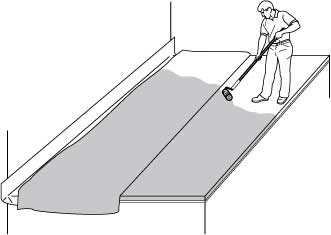

STEP 18: Using a large roller or push broom, apply

pressure to the surface of the rubber to assure proper bonding.

STEP 19: Reach under the overhanging rubber and

strip the protective paper from the Termination Tape.

STEP 20: Slit the corners of the rubber with a utility

knife so the overhanging rubber can drop into place.

STEP 21: Form the rubber around the roof

edge and press the rubber into the tape.

STEP 22: Firmly roll the rubber at the

roof edge to insure a good bond.

STEP 23: Clean the slit corners with

toluene,

naptha, or white gasoline.

STEP 24: Seal the slit corners with

Uncured

Laminate Tape. See EDGE TRANSITIONS.

STEP 25: Screw Wall Termination Bars

through the rubber and Termination Tape.

STEP 26: Apply Silicone Caulk for EPDM to

the back of the Drip Edge Termination Bars

STEP 27: Screw the Drip-Edge Termination

Bars through the rubber and Termination Tape.

STEP 28: Screw short lengths of Wall Termination Bars to

connect the bars on the wall and edges, sealing the perimeter.

STEP 29: Carefully trim the rubber to the underside

of the termination bars with a sharp utility knife.