General Information

General InformationGreen Roofs

Rainwater Harvesting

Ponds and Wetlands

Energy-Efficient Building

Waterproofing

EPDM Roofing

Preparation

Basic Procedure

Multiple Walls

Details

Folded Inside Corners

Molded Inside Corners

Taped Inside Corners

Molded Outside Corners

Taped Outside Corners

Posts

Skylights

Outside Edges

Inside Edges and Sills

Edge Transitions

Pipe Boots

Curved Penetrations

Roof Drains

Scupper Drains

Overlap Seams

Butt Seams

Edges

Coverings

Components

Acrylic Roofing

Documents

EPDM ROOFING: COVERINGS

While Conservation Technology EPDM is a tough material that can withstand frequent foot traffic and considerable abuse, it can be easily cut with a sharp object. When a roof is to be used as a recreational deck, it should always be covered with a hard wear surface. Covering the rubber will prolong its life by shielding it from the sun, can reduce heat transmission into the building, can protect the roof from falling branches, can improve the fire resistance of the roof, and can enhance the appearance of the building. Covering materials also prevent wind uplift, thereby eliminating the need to fully adhere rubber membranes. Following is a sampling of the dozens of surface treatments that can be effective:

installing a wood deck

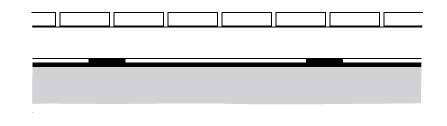

CONTINUOUS WOOD DECKS: The simplest walk surface is a single wood deck that spans the entire roof. Typical construction might be 2 x 4 sleepers laid on edge with 2 x 6 deck boards screwed in place. Protective pads of scrap rubber should be placed between the sleepers and rubber roof. Posts and railings should be attached to the deck or the roof fascia and not through the roof. The deck perimeter should be anchored to the fascia or surrounding walls to prevent wind uplift and shifting.

cross-section through wood deck on continuous sleepers

installing a pallet deck

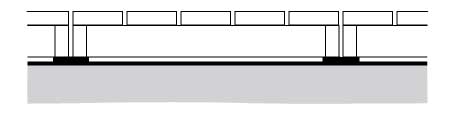

PALLET DECKS: If easier access to the roof is desired, a wood deck can be build as a grid of pre-assembled deck sections or “pallets” that just sit on the rubber. Typical construction might be 2 x 4 frames measuring four feet square with 5/4 x 6 deck boards. Protective pads of scrap rubber should be placed between the sleepers and rubber: these can also be used to shim the pallets level. Posts and railings should be attached to the pallets or the roof fascia and not through the roof. The perimeter pallets should be attached to each other and anchored to the fascia or surrounding walls to prevent wind uplift and shifting.

cross-secton of wood pallet deck

installing a paver deck

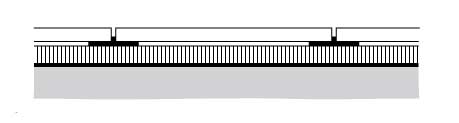

PAVER DECKS: Roof pavers are high-strength concrete paver blocks measuring 18”x18”x1-3/4” or 24”x24”x 1-3/4” that are specifically formulated for rooftop patios and plazas. They can be laid on a base of gravel or on “pedestals”, molded plastic supports that lift the pavers off the roof and space them uniformly. Paver decks reflects heat and can also provide an inexpensive means to insulate low-slope roof: boards of extruded polystyrene insulation are simply laid over the rubber, a protection fabric is unrolled over the insulation, and the paver pedestals are placed over the fabric. The only drawback of the pavers is their weight, typically 25 pounds per square foot.

cross-section of a paver deck with rigid insulation

installing a tile roof

TILE ROOFS: Tile should never be applied directly to rubber because some setting compounds can damage rubber and even with safe compounds the tile will eventually crack. For a safe and durable installation, first apply a base of one-inch fine-aggregate concrete, often called “sand-mix” concrete, reinforced with a mesh or with fibers. After the base has dried, the tile can be laid using a standard thin-set compound. If the roof measures more than 20 feet in any direction, a plastic slip sheet such as our Tenoarm film should be laid between the concrete and rubber. and expansion joints should be created in the tile and concrete every 20 feet. Tile roofs are not recommended for regions with frequent winter freezing.

cross-section of tile roof on concrete setting bed

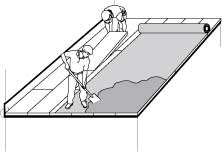

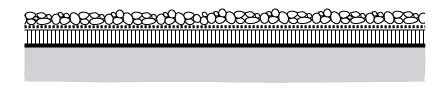

installing a gravel roof

GRAVEL BALLASTED ROOFS: Gravel can be applied over a rubber membrane to reflect heat and to provide an inexpensive means to insulate a low-slope roof: boards of extruded polystyrene insulation are simply laid over the rubber, a protection fabric is unrolled over the insulation, and gravel is spread at the rate of 10 - 15 lbs per square foot. Gravel should be 1/2” to 1 1/2” in size, have rounded edges, and be thoroughly washed to remove all sand and grit.

cross-section of gravel ballasted insulation

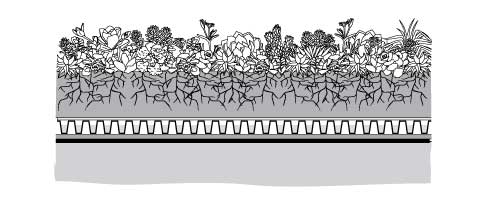

installing a green roof

GREEN ROOFS: Green roofs eliminate summer heat gain, delay and reduce stormwater runoff, provide wildlife habitat, and transform rooftops into garden space. One common type of green roof design consists of a water-storing protection fabric, a plastic water-holding drainage sheet, a soil-separation fabric, and a specially engineered green roof soil. Since Conservation Technology EPDM is root resistant, a separate root barrier is not required. Insulation can be applied over the membrane, just as with paver decks and gravel ballasted roofs. For more detailed information about green roofs, see GREEN ROOFS.

green roof section