General Information

General InformationGreen Roofs

Rainwater Harvesting

Ponds and Wetlands

Energy-Efficient Building

Waterproofing

EPDM Roofing

Preparation

Basic Procedure

Multiple Walls

Details

Folded Inside Corners

Molded Inside Corners

Taped Inside Corners

Molded Outside Corners

Taped Outside Corners

Posts

Skylights

Outside Edges

Inside Edges and Sills

Edge Transitions

Pipe Boots

Curved Penetrations

Roof Drains

Scupper Drains

Overlap Seams

Butt Seams

Edges

Coverings

Components

Acrylic Roofing

Documents

EPDM ROOFING: INSIDE EDGES AND SILLS

TAPED INSIDE EDGES: An inside edge is created when two roof edges intersect at an angle less than 180°. In order to fold the rubber over both edges, the roof membrane must be cut at a 45° angle to both edges. A square of Uncured Laminate Tape placed on the roof surface, overhanging the roof edge, can be stretched and formed to make contact with all surfaces, sealing the corner slit. Bonding Adhesive, Termination Tape, and Termination Bars assure a watertight edge.

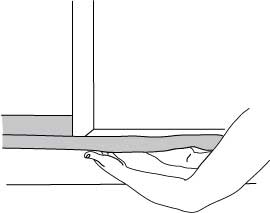

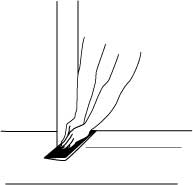

STEP 1: Cut the overhanging

rubber at a 45° angle to both edges.

STEP 2: Fold and adhere the rubber

over both edges, pressing into the tape.

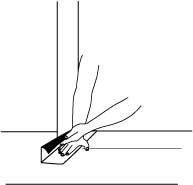

STEP 3: Place a square of Uncured Laminate

Tape so that it extends 2” over the roof edge.

STEP 4: Begin to stretch the

tape downward over the edge.

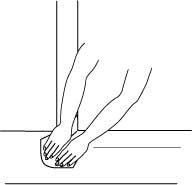

STEP 5: Finish forming the tape until

it stretches and bonds to all surfaces.

TAPED DOOR SILLS: If door sills can be flashed before the door frames are installed, the rubber roof membrane can create a drip pan under the door that will eliminate the possibility of water leakage. Frame the opening at least 6” higher than the roof surface with the sill plate sloping slightly towards the exterior. Adhere the rubber up the wall (covering the door opening), slit the rubber, form the rubber over the door sill, and seal both sides of the opening using Uncured Laminate Tape.

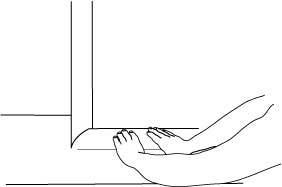

STEP 1: Adhere the rubber sheet to

the

wall continuing above the sill plate.

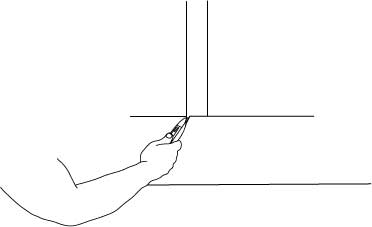

STEP 2: Cut a vertical slit on

both sides of the door opening.

STEP 3: Fold the rubber over the

door sill

and adhere it in place.

STEP 4: Position a strip of Uncured Laminate

Tape so that it extends 2” over the roof edge.

STEP 5: Lift the tape to

make contact with the wall.

STEP 6: Form the tape over the edge so

that it stretches and bonds to all surfaces.