General Information

General InformationGreen Roofs

Rainwater Harvesting

Ponds and Wetlands

Energy-Efficient Building

Waterproofing

EPDM Roofing

Preparation

Basic Procedure

Multiple Walls

Details

Folded Inside Corners

Molded Inside Corners

Taped Inside Corners

Molded Outside Corners

Taped Outside Corners

Posts

Skylights

Outside Edges

Inside Edges and Sills

Edge Transitions

Pipe Boots

Curved Penetrations

Roof Drains

Scupper Drains

Overlap Seams

Butt Seams

Edges

Coverings

Components

Acrylic Roofing

Documents

EPDM ROOFING: MOLDED OUTSIDE CORNERS

Molded Outside Corners are used to seal the outside corner formed when two walls project into a roof. We pre-apply seam tape to the horizontal flanges which extend 5” onto the roof and to the vertical flanges which extend 8” up the walls. Position the corners carefully and work slowly to avoid creating gaps at the intersections of the roof and walls. Note that Molded Outside Corners can only be applied to 90° corners: for other angles see TAPED OUTSIDE CORNERS.

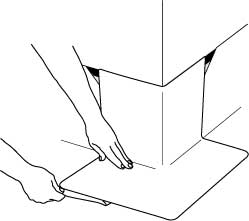

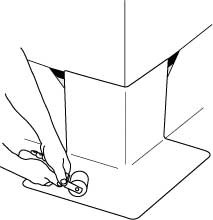

STEP 1: Cut a 45° slit at the corner

and adhere both sides to the wall.

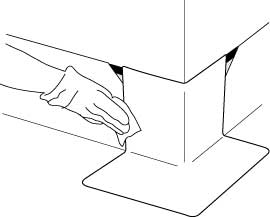

STEP 2: Clean all surfaces with

toluene, naptha, or white gasoline.

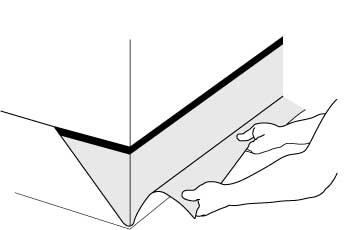

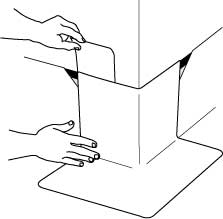

STEP 3: Peel back the protection paper

to expose the tape at the bottom corner.

STEP 4: Holding the corner firmly in

place, press

to tack the corner to the roof.

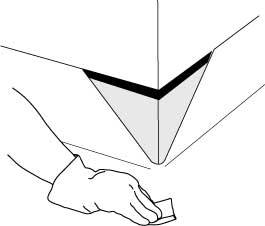

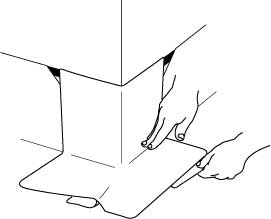

STEP 5: Reach under and pull the

protection paper towards one side.

STEP 6: Continue to pull, pressing the

molded corner firmly into the roof corner.

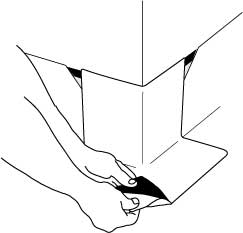

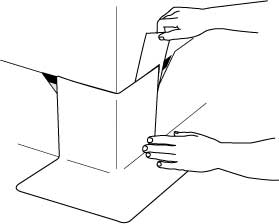

STEP 7: Reach under the other side and

pull the protection paper towards the side.

STEP 8: Continue to pull, pressing the

molded corner firmly into the roof corner.

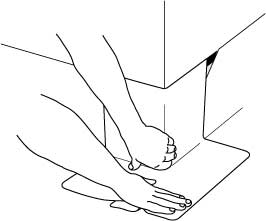

STEP 9: Roll all surfaces firmly,

especially at the roof corners.

STEP 10: Clean the edges with

toluene, naptha, or white gasoline.

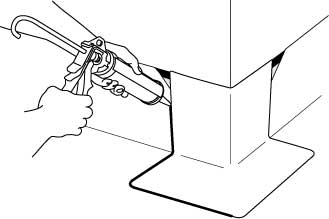

STEP 11: Caulk around the molded

corner with Silicone Caulk for EPDM.