General Information

General InformationGreen Roofs

Rainwater Harvesting

Ponds and Wetlands

Energy-Efficient Building

Waterproofing

EPDM Roofing

Preparation

Basic Procedure

Multiple Walls

Details

Folded Inside Corners

Molded Inside Corners

Taped Inside Corners

Molded Outside Corners

Taped Outside Corners

Posts

Skylights

Outside Edges

Inside Edges and Sills

Edge Transitions

Pipe Boots

Curved Penetrations

Roof Drains

Scupper Drains

Overlap Seams

Butt Seams

Edges

Coverings

Components

Acrylic Roofing

Documents

EPDM ROOFING: SKYLIGHTS

With careful preparation, skylight sidewalls can be flashed with the same rubber sheet as the roof. Before the rubber roof is installed, frame the skylight openings and cut out the sheathing over the openings. Then re-install the cut panel on temporary wood blocking to cover the openings. When the rubber sheet is installed, apply adhesive to the back of the rubber as usual, but do not apply adhesive over the skylight panel. Poke holes through the four corners of the opening and carefully cut a small round circle at each hole to prevent tearing. Then follow the illustrated procedures. As an alternative, the skylight corners could also be taped (see TAPED OUTSIDE CORNERS).

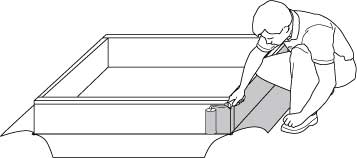

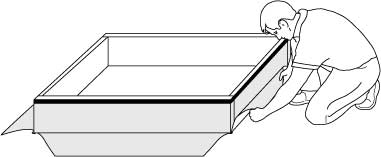

STEP 1: Mark and cut four flaps slightly wider than the

height of the skylight curb and with 45° corner slits.

STEP 2: Fold back the four flaps and lower

the skylight curb into positon.

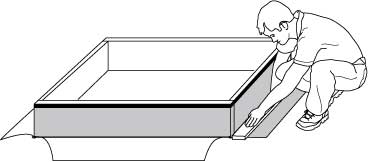

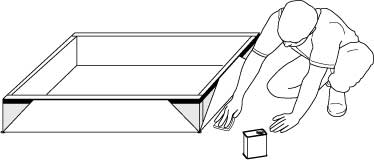

STEP 3: Apply Termination Tape around the top edge of

the curb. Do not remove the protective paper.

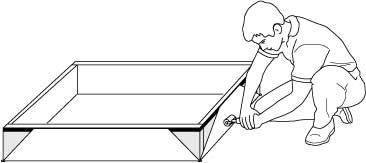

STEP 4: Apply Bonding Adhesive to the exposed rubber

and the skylight curb using a narrow paint roller.

STEP 5: Using a clean board, press the rubber firmly

into the corner where the roof and curb meet.

STEP 6: Strip the release paper from the tape and

lift the sheet, pressing it into the adhesive and tape.

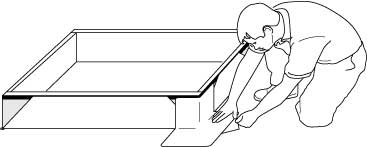

STEP 7: Firmly roll the rubber on

the curb

to insure a good bond.

STEP 8: Clean all surfaces with

toluene, naptha, or white gasoline.

STEP 9: Install four molded inside corners, following

the instructions for MOLDED OUTSIDE CORNERS.

STEP 10: Roll all surfaces of the

molded corners and skylight sidewalls.

STEP 11: Clean all surfaces with

toluene, naptha, or white gasoline.

STEP 12: Overlap a strip of Cured Laminate Tape to seal

the triangular areas not covered by the molded corners.

STEP 13: Roll all surfaces firmly,

especially at the roof corners.

STEP 14: Clean the edges

one

final time before caulking.

STEP 15: Caulk around the molded corners

and

Laminate Tape with Silicone Caulk for EPDM.